|

You have a great concept, but you don’t know the first thing about apparel development. What should you expect? Maybe you have been working with a product developer or factory but you don’t know if your experience is normal. There is a lot to know, but here are some basics.

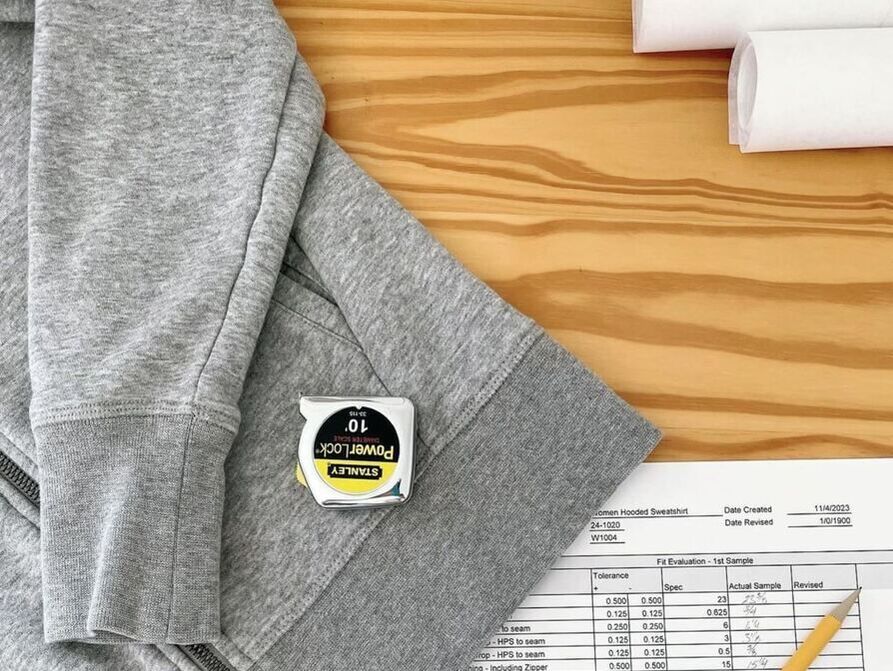

How long does development take? The timeframe to develop a product before cutting and sewing can start takes anywhere from 6-18 months. Fast fashion retailers can shorten that but if you are starting out, the development timeframe before you start production will be at least six months. You need to locate the right fabric and trims. Patterns need to be made. Samples need to be made and fit on models and then adjusted. Production needs to be booked ahead. Unless you somehow take pre-orders, this means you won’t begin to generate cash as a new company for months. Frustrating yes, but planning accordingly helps to both shorten the timeframe and stay energetic about your new venture. If you are trying to figure out the timeline for your own project this previous post on building a product development schedule will be helpful. How many samples is normal? Usually, 2-3 physical development samples are needed to work through decisions about style, fit and to validate the factory understands how you want the product produced. Knowledgeable staff and a communicative factory can help to reduce the number of samples. These samples are usually made in one size. If you want to review a size run, one sample in every size, discuss this upfront with the development team and factory. Don’t get frustrated if you are working on a collection of several styles and one piece takes additional samples to develop. Some products are simply more challenging than others. If you need photo samples in addition to your development samples or in a different size, plan those into your budget. Minimum Order Quantities Factories and fabric mills have minimums. This is an important starting point in conversations with factories and fabric and trim suppliers. The more you order, the lower the cost. As a start-up this is a trade-off with staying flexible and not spending too much cash up front. Garment manufacturers will have minimums for both styles and SKUs (stock keeping units). For example, a small batch manufacturer may have a minimum of 300 pieces per style and 50 pieces per SKU. This means if you want to run six sizes you must only have one colorway. 50x6 = 300. Or you could run three sizes in two colors and order 50 units of each. This is simplifying because usually the order will be larger for certain sizes or colors and smaller for others. Expect to pay more per unit for small batch manufacturers (low minimums). The advantage is that you won’t need to hold large amounts of inventory. You will learn quickly what sells and can then place a reorder. This is a better alternative for those starting out. You will sell more at full price and learn what your customers want. Look for fabric suppliers specializing in stock fabrics that are already produced. Be sure those fabrics are always kept in stock and available for reorder. Stock fabric suppliers will have lower minimum order quantities. They could range anywhere from 5 yards to 100 yards or more. Don’t forget to figure in shipping when determining the total cost. Stock fabric suppliers can usually ship fabric immediately upon receiving your order. Fabric mills who only produce upon receiving an order typically have significant minimum order quantities. There are good reasons for this. Setting up equipment to produce a fabric can take as long or longer than actually knitting or weaving the fabric. Dye batches for a particular color are determined by the size of the equipment. Minimums might be different depending on the weight of the fabric. If you are just getting started, meeting minimums of 1,000+ yards will be tough. Lead times can be long. Expect it to take 6-8 weeks for a custom fabric order to be produced and shipped. Development Cost Costs for development and production differ based on the complexity of the product, where you are manufacturing and the skill of the team you have assembled. Budget $2,000 to $6,000+ for developing each style. Some overseas manufacturers will fold the development costs into the quoted cost of goods. While convenient for some business models, the lack of transparency means you’ll never know what you are spending on development. If you work this way, you or someone on your team will need the skills to put together a technical package. If your factory, patternmaker, or technical designer charge you line item fees for product development and patterns; you’ll know how much you are spending. Regardless of how you are charged, a technically knowledgeable team will make the process go faster and produce a better product in the end. Service providers (designers, tech designers and patternmakers) will either provide their hourly rate or give you a quote based on your project or styles. If they provide an hourly rate, ask them for an estimate of the hours they think a style will take based on the complexity. The lowest hourly rate isn’t always the cheapest. A higher rate could mean they are more skilled and have access to additional software and tools. They may also have a network of other service providers they can help you meet. Look for service providers and factories with great communication skills. They will save you massive amounts of time in the long run. Samples usually cost three to four times the cost of goods at the production stage. If your production cost for a style is $25 for all labor and materials, each sample will cost $75 to $100. Don’t forget to calculate in shipping to get materials to the sample maker or factory and shipping to get the sample to you for evaluation. Overwhelmed If the product development process seems daunting and you are feeling overwhelmed, that’s normal. Break the process out into tasks. Set time goals for each task that will move you toward the final goal of launching your product or collection. Perseverance and discipline are the keys to making your vision into a reality. Launching any business is scary. There is an additional mental load for designers putting their art out into the world for the first time. You are exposing your vision to the world to critique. If you reach a frustration point, take a mental check of what’s causing the frustration. Then take a deep breath and tackle the next item on your task list.

0 Comments

Leave a Reply. |