|

Everyone is fighting for market share. Slow fashion is becoming trendy. Shoppers are being thoughtful about where and how they spend their money. How do you stay profitable when growth within the apparel sector slows? There are ways to better serve your current customers so you retain them and find new customers without spending wildly trying to keep up with the latest social media trends.

Evaluate Your Size Range If you only run XS-XL regular sizes there is opportunity to gain additional customers by expanding the size range. What percent of your sales are in XL? Perhaps you need to add 2 and 3X. The best fitting extended size ranges take extra care and often fit on a separate base size because the body shape is different. Additional development is necessary but it’s easier than adding new styles to the assortment. Test running petite and or tall products. We can create petite and tall patterns simply by following rules to adjust the patterns without refitting each style. Customers who struggle to find clothing that fits are the most loyal when they find companies who serve their needs well. Get a Handle on Returns How many of you have returned an item to a store and not even been asked why? Too many companies have given up trying to get to the root cause of returns. Customers don’t buy a garment with the hope of returning it. You have disappointed a customer if they are making a return. These are people who are interested in your products. Not caring why they returned a garment is giving up on someone who already voted yes for you. I meet companies who have the data they need but never look at it. For some, the manner in which the data is gathered makes it impossible to aggregate. They want a magic solution to help consumers find the right size, but meanwhile it could be the shape of the garment that doesn’t fit. Raise Your Retails Our purchasing power as US consumers has eroded 22.3% since January 2020. Yet, apparel retails have only increased 10.6%. Apparel retails falling in proportion to other products has been normal over years and years as retailers chase cheaper labor. Costs have been driven down while the overall quality has eroded. Now is the time to focus on adding value through quality. Selling less at a higher price point for the same gross sales dollars is almost always more profitable. If your clothing cost less than a tank of gas and much less than a trip to the grocery store, the consumer perceives it as a perishable product. Yet, designers, patternmakers, cutters and sewers put in time and effort to make the product. Shouldn’t it be worth more than products that last you a week or two? Raise Perceived Quality What’s your customers experience when they receive their garment? Many companies are simply placing garments in plastic mailers these days. Are you selling $80 shirts and shipping them the same way companies selling $20 shirts do? Try wrapping the product in custom printed tissue with a sticker. Better yet, add a hand written note. Even better, add a card or paper they can fill out IF they return the product explaining why! It can be reason codes with check boxes or a place to jot a note. Raise your retail to cover the additional packaging. You might find that a few cents of extra packaging add a couple of dollars in perceived quality. Be creative and personal. Create a positive experience whether they are shopping in store or from home. Make sure the website and digital marketing live up to the experience you want the consumer to have.

0 Comments

Since launching Fireflyline I’ve worked with a number of organizations that produce uniforms. The companies have covered many markets including grocery stores, military, school uniform and protective apparel. Organizations producing uniforms have unique needs compared to other apparel retailers. Consistency of Fit Consistency of fit across styles is important for any apparel retailer but is absolutely critical for those selling uniforms. If someone purchases a size extra-large polo shirt then they also expect the size extra-large jacket or woven shirt to fit them properly. Employees placing uniform orders don’t frequently have opportunities to try on their uniform. If their uniform wears out they expect they can replace the items by purchasing the same size. Consistency can be achieved through multiple steps. Measurement specs for new products should be compared to current styles. The grading (increases and decreases between sizes) used should be consistent across all types of products. New styles should be started based on established block patterns. If the patternmaker follows the same block pattern for multiple styles, they will have similar shapes in addition to measurements. All production should then be audited to verify the factory achieved the desired fit and all points of measurement are within established tolerances. If sizing changes are made to improve the fit of a product, it’s critical to track how the changes impact both sales and satisfaction. Satisfaction can be tracked through returns or client feedback. Anecdotal evidence isn’t actionable. Companies need to track the percent of each product returned and why it was returned. They also need to capture customer comments, reviews and feedback in a manner that can be consolidated to track trends. Extensive Size Ranges Normally I tell brands not to try and fit everyone. Select a group of sizes and focus on creating great product for that market. But for uniforms, you really do need to fit everyone. There might be fitness standards that refine the size range, such as protective apparel for firefighters. But for a uniform company producing polos for employees at big box stores they are going to need a huge range of sizes. I often grade knit tops from XXS to 7X for these companies. They may order only a few units of the largest or smallest sizes or they may only produce those sizes as special orders. Either way there will always be someone outside of the size range. Production of single garments for unique situations needs to be considered ahead of time and accounted for in costs. Discuss these needs with your factory when initially costing the production. Fitting everyone well can require creating options for multiple body shapes such as curvy and straight fit pants for women or slim, husky and regular kids’ styles for school uniform. The number of stock keeping units (SKUS) can quickly escalate. Don’t Try and Create Unique Sizing Systems There are no body measurement standards for women in the US apparel industry. A woman who is a 6 in one brand could be a 10 in another brand. A size Small might be a 4-6 for one company and an 8-10 for another company. Do the research and try and be similar to competitors and the retail brands that you think are shopped by the end users. There are standards and research available from organizations like ASTM and Alvanon. Put in the work. Don’t create a really unique sizing system that the final consumer can’t follow. Menswear and Children’s apparel is a bit more standardized in the US so follow US ASTM standards or recommendations from a service provider like Alvanon. Understand what other companies are doing and compare your own grades to competitors every few years to validate. Product Line + Custom Offering both an existing product line and customizations for retail companies can be a huge advantage. Those customizations should focus on style, not fit unless the client has a very particular niche. Customizations can be as simple as a colorblock or custom embroidery or as complex as a specially designed product line. Avoid creating unique size standards or custom fits for separate companies. If car rental agency A has a blue fleece jacket and car rental agency B comes to you for uniforms; you want to be able to offer the same jacket in red without having to refit and resize the whole style. Only if the client has a unique niche market should the fit be altered for a specific industry or client. More companies are realizing that their brand is represented in everything they do. This includes what their employees wear. Service companies such as hotels and restaurants can create unique brand messaging through customized uniforms. Presenting custom designs to companies outside the apparel industry can be challenging. Traditional fashion illustrations or flat sketches may not tell the desired story to executives working in other industries trying to select uniforms for their employees. I’ve assisted clients who produce uniforms by creating 3D renderings of garments in the proposed designs. 3D can be easier for clients to visualize and we can create the 3D renderings in any sizes desired. Viable for US Manufacturers

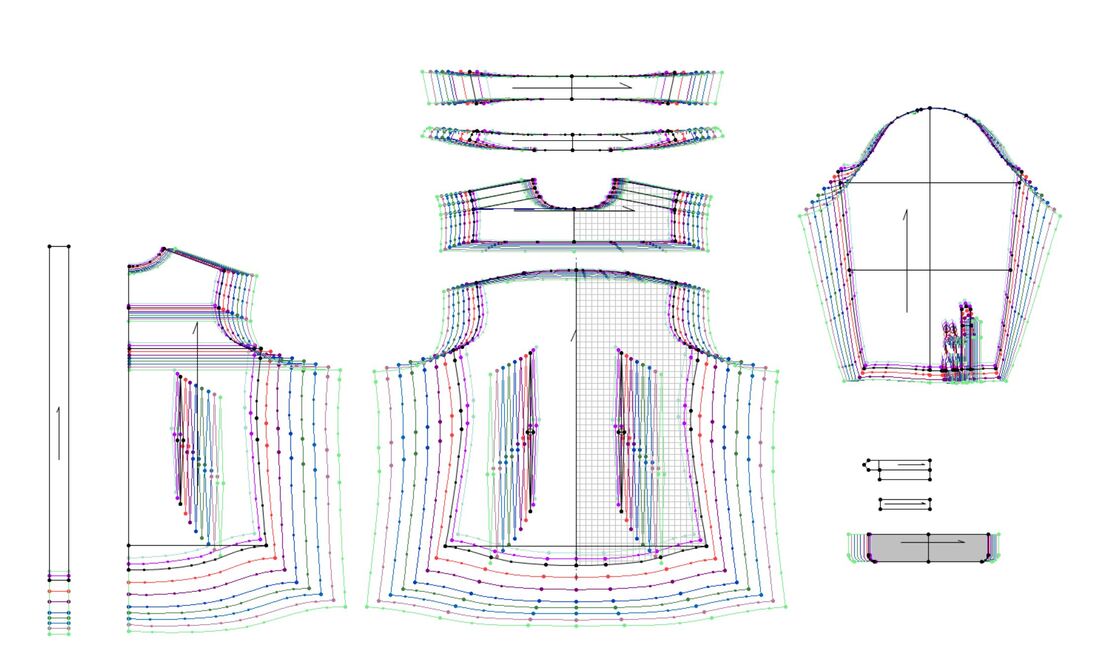

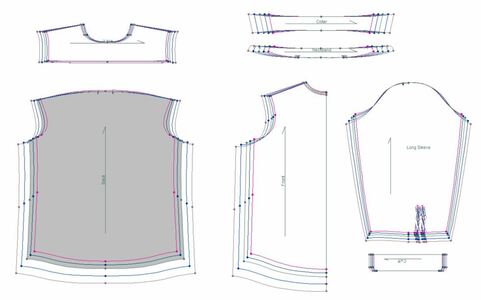

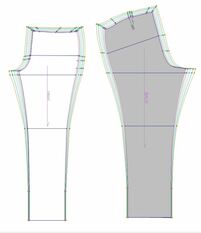

Uniforms are steady, non-seasonal business. Uniforms don’t need to be redesigned every few months. This makes them an attractive proposition to factories. Many of the styles are simple and fabrics are frequently shared across many styles. Lead times can be critical to fill large orders from corporate clients. Manufacturing uniforms in the US is not only possible but can be an advantage. The US military and many municipalities require US production of uniforms so the skills to produce these items still exist within US factories. Manufacturing costs are frequently higher but don’t forget to calculate all logistical costs when comparing to overseas production costs. US manufacturing isn’t usually the right fit for cost competitive polyester/cotton polos sold to industries with high employee turnover such as grocery or big box retailers. But US manufacturing can be a great fit for uniforms focused on specialty service industries or protective apparel. Clients are sometimes puzzled why an apparel pattern-maker or pattern grader asks so many questions. As a pattern grader I want to be sure your designs fit your customers. Your customers should be able to buy the same size each time they make a purchase. The work I do must be both accurate and consistent. The grade should be consistent between the styles I work on and the styles anyone else has graded for you. You might think there are hard and fast rules to grading garments. There are not. Asking questions demonstrates your grader knows what they are doing. No one is questioning the skills of a pattern grader you have used previously. We want to help you create a consistent fit. When should you worry? When your pattern grader doesn’t ask questions. If you tell them you want to run the style in women’s sizes 2-16 and the grader doesn’t ask anything before grading, that is a problem! There is no industry standard for how much each size should grade. You put in a lot of work to get to this point. You have created a garment that fits great in one size. A well graded pattern maintains the integrity of this work across all sizes. A poorly graded pattern jeopardizes all your hard work to date. Questions Your Pattern Grader will ask? What’s your base size? This is the original size the pattern was created to fit. Who is your target customer? Age? Fitness level? Ethnicity? Will the style be alpha or numeric? Alpha sizes are combined sizes, like a women’s Medium (8-10). If alpha which sizes are combined? Equivalent sizes are pretty consistent in the industry for men but alpha size equivalents for women change between brands. A women’s size Medium might be 6-8, 8-10 or 10-12. Size Charts A basic size chart like you use on your website to help your customers find the right size, tells us your basic body width grade. Unfortunately, the size chart usually only gives us basic width measurements such as chest, waist, and hip. The size chart doesn't tell me your customers are mountain climbers in which case I will grade the shoulder width differently than for a brand marketed to seventy-year-old bird watching enthusiasts. Below is a picture of a graded shirt. Each dot is a grade point. You can see the chest, waist, and sweep are only a few of the points graded.  Measurement Charts from Previous Styles If you have been developing apparel for multiple seasons, you may already have a graded measurement chart for the new style you want graded. Your pattern grader should follow that chart. If not, the grader may ask to see charts from previous styles. Measurement charts are usually included in technical packages/specifications. If one person created all previous measurement charts for your brand, they should follow a consistent system. All neck widths should grade the same. All body lengths for knit tops should grade the same. All long sleeves should grade the same. More points are included than the size chart. Previous Graded Patterns The holy grail! Previously graded patterns tell us the grade points on the measurement chart but additional things like the grade distribution and additional grade points that may not be on the measurement chart. Measurements like armhole depth are not frequently included on a garment measurement chart; but help your grader more than the final armhole circumference. Reviewing the grade distribution on pants is especially important. Many people in the industry have different opinions on how much of the grade to place at the rises versus the side seams. I can achieve the same measurements as someone else but the distribution might be different. Usually the goal is to keep every size shaped the same. Occasionally we will break that rule. As an example, we may allow the front rise angle to shift if you think your customers over a certain size have a more pronounced belly. If we ask to see a previous pant you have run; we are only asking to confirm the grading “philosophy” that has been used on your styles in the past. Will we blindly copy your previous patterns? No. If we find something unusual, we will ask you about the issue. There may be a valid reason the pattern is graded that way. But we won’t perpetuate an error. Don’t Worry If You Don’t Have Answers If you don’t have the information requested by the pattern grader, don’t worry. I will gladly help my clients determine the right grading for their target market. I do charge a consulting fee for this work. I do not make the same recommendation to every client. We discuss who your competitors are and the demographics of your target market. I’ll review your competitors’ grades and size charts. I’ll review available anthropometric data for your target market. I’ll grade the type of styles you intend to create before finalizing the grade. Then I’ll create a template that all your measurement charts can be started from to maintain consistency. Sometimes we meet well established brands that have several different factories making products and they have relied on the factory for pattern-making and grading. Unfortunately, I can almost guarantee inconsistencies. Pattern-makers and graders do great work, but every grader and pattern-maker has their own methods. If you are in this situation, you need to create consistent measurement grade rules and graded block patterns. Block patterns are appreciated by graders. They can import a digital block pattern and copy the grade rules directly to the new style. Using graded blocks guarantees consistency in grading. This way you can work directly with the best factory for the product type without worries about consistency. For more information on grading visit our previous post on Reviewing Nested Graded Patterns. For more information on what a block pattern is, we recommend What is a Block from Fashion-Incubator. Copyright 2019 Fireflyline LLC |