|

Everyone is fighting for market share. Slow fashion is becoming trendy. Shoppers are being thoughtful about where and how they spend their money. How do you stay profitable when growth within the apparel sector slows? There are ways to better serve your current customers so you retain them and find new customers without spending wildly trying to keep up with the latest social media trends.

Evaluate Your Size Range If you only run XS-XL regular sizes there is opportunity to gain additional customers by expanding the size range. What percent of your sales are in XL? Perhaps you need to add 2 and 3X. The best fitting extended size ranges take extra care and often fit on a separate base size because the body shape is different. Additional development is necessary but it’s easier than adding new styles to the assortment. Test running petite and or tall products. We can create petite and tall patterns simply by following rules to adjust the patterns without refitting each style. Customers who struggle to find clothing that fits are the most loyal when they find companies who serve their needs well. Get a Handle on Returns How many of you have returned an item to a store and not even been asked why? Too many companies have given up trying to get to the root cause of returns. Customers don’t buy a garment with the hope of returning it. You have disappointed a customer if they are making a return. These are people who are interested in your products. Not caring why they returned a garment is giving up on someone who already voted yes for you. I meet companies who have the data they need but never look at it. For some, the manner in which the data is gathered makes it impossible to aggregate. They want a magic solution to help consumers find the right size, but meanwhile it could be the shape of the garment that doesn’t fit. Raise Your Retails Our purchasing power as US consumers has eroded 22.3% since January 2020. Yet, apparel retails have only increased 10.6%. Apparel retails falling in proportion to other products has been normal over years and years as retailers chase cheaper labor. Costs have been driven down while the overall quality has eroded. Now is the time to focus on adding value through quality. Selling less at a higher price point for the same gross sales dollars is almost always more profitable. If your clothing cost less than a tank of gas and much less than a trip to the grocery store, the consumer perceives it as a perishable product. Yet, designers, patternmakers, cutters and sewers put in time and effort to make the product. Shouldn’t it be worth more than products that last you a week or two? Raise Perceived Quality What’s your customers experience when they receive their garment? Many companies are simply placing garments in plastic mailers these days. Are you selling $80 shirts and shipping them the same way companies selling $20 shirts do? Try wrapping the product in custom printed tissue with a sticker. Better yet, add a hand written note. Even better, add a card or paper they can fill out IF they return the product explaining why! It can be reason codes with check boxes or a place to jot a note. Raise your retail to cover the additional packaging. You might find that a few cents of extra packaging add a couple of dollars in perceived quality. Be creative and personal. Create a positive experience whether they are shopping in store or from home. Make sure the website and digital marketing live up to the experience you want the consumer to have.

0 Comments

Offering quality and value to your customers means building clothing that meets the customer’s expectations. Meeting your own expectations, those of your CEO, or anyone’s impression of the customer’s expectations is not enough. You need to capture the voice of the customer. If you offer a wide range of product to various customer demographics you may need to develop product specific to the needs of each customer group. Knowing the customer’s expectations does not make your designs less creative. In fact, it helps push the creative process in new directions. Think of the boundaries set by customer needs like a party theme that creates a cohesive direction when planning party food and decor. You will still have plenty of artistic freedom. Tools to learn customer’s quality expectations:

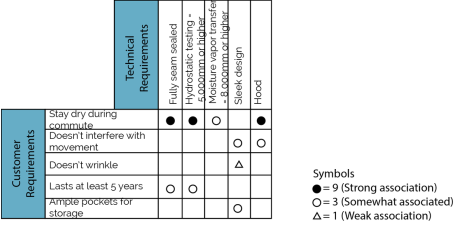

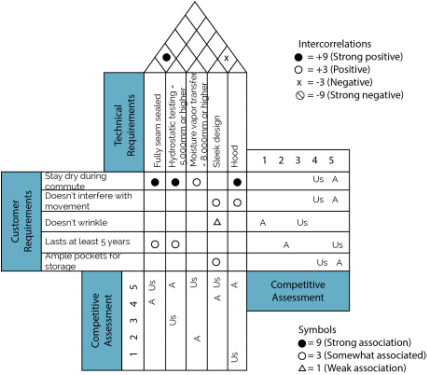

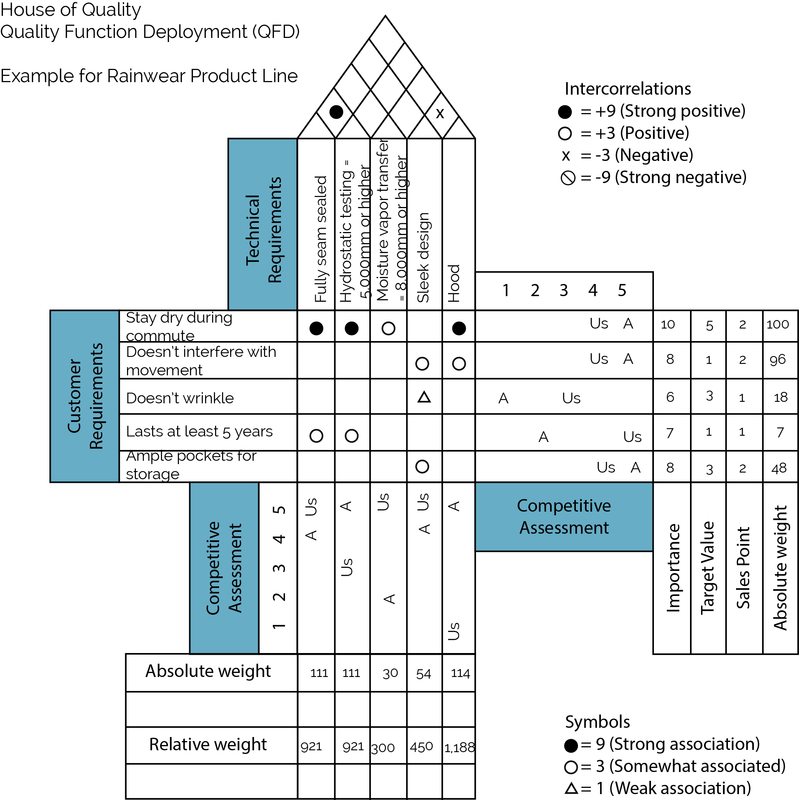

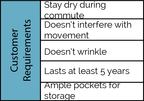

Choose multiple methods and include at least one which allows you to prioritize, not just gather feedback. You want to find out what features but also how important those features are in relationship to each other. Focus groups and surveys allow you to ask customers to rank what features are most important in various types of garments. As an example, we will pretend to build a new line of rainwear for urban commuters. We know they will wear the coats and jackets while traveling via train, car, and bus. We can select multiple cities and conduct surveys of customers who fit our demographic profile. We will ask not only what features customers would like in a raincoat but also which features are most important. Our completed survey indicates the features in the chart to the left are the most important to our customers. Next we sit down as a team to record our normal technical requirements for a raincoat. Most of our raincoats are waterproof and seam sealed, so we list the fabric standards required. The garment will need a hood and our current brand aesthetic leans toward sleek silhouettes. Analyzing our customer requirements versus our technical requirements tells us where they are in agreement or where we need to improve to meet customers’ expectations. We will assign a symbol (or you can use numbers) to demonstrate as shown in the chart below. Two additional steps will help us to thoroughly understand the product. Do our technical requirements all work together? Or will succeeding at one defeat another? Fabric which can be seam sealed usually passes a waterproof test for hydrostatic resistance at the specified level, so those features have a high positive correlation. Adding a hood may impede our sleek design, so those features have a slightly negative correlation. Record these items above the technical requirements as shown below. Then we will analyze how we compare to a competitor for each of the customer requirements and technical requirements. For example, our standard for hydrostatic resistance is 5,000mm but competitor A typically uses fabrics which test at 10,000mm. We will rank us at a 3 and our competitor at 5 in our chart. (Want to know what a test for hydrostatic pressure is?). Do this exercise for as many competitors as needed. Finally we will assign a last group of numbers and do some math. Ugh! If you are already tired of numbers and charts you can stop here. The important point is that you have learned what features are important to your customer and have shared that information with the whole product team. But for those of you who love charts and quality management, we will finish the chart. Remember, how we asked the customers to rank how important each of the features were? Fill out the importance column with a 1-10 ranking. 10 being it is the most important feature to the customer. As a team, determine which features you want to target improving. Use the target column to give each a 1-5 rating. Five means you will improve the feature to beat the competition, 3 means you will make some improvements, one means you will leave it the same. Finally, ask the sales team (or the customers) which features would impact sales. A 2 indicates sales will be impacted and a 1 means sales will not be impacted. For instance, our customer can’t determine how long the garment will last when buying so we will give “lasts at least 5 years” a rating of 1. Almost done, if you stick with it you'll be a quality guru!. We just need to do some math. Multiply the importance x target value x sales point to get the absolute weight of the customer requirements. Once completed we see that stay dry during commute is our most important customer requirement! Example: Stay dry during commute 10 x 5 x 2 = 100 Absolute weight Remember, those numbers associated with the symbols? We will now use those to calculate absolute weight using the relationships between the customer and technical requirements. Multiply the number associated with the symbols in each column times the importance value. Example: Fully seam sealed 9 x 10 + 3 x 7 = 111 Finally, use the same relationship numbers but multiply times the absolute weight of the customer requirements to reach the relative weight. Example: Fully seam sealed 9 x 100 + 3 x 7 = 921 Whew, you are done! What does all this mean? It means, your garment really needs a hood, waterproof fabric, and seam seal tape. You already knew that, didn’t you. But did you know that it was more important than the fabric being breathable and the sleek design? It really isn’t the finished chart that is helpful, but the process you go through as a team to complete the chart. Also, you now know where trade-offs can be made during the design process. Now you can start designing! This process is known as quality function deployment (QFD). While it isn’t commonly used for apparel, it is often used for new product development projects. In fact if you were building an airplane, you would likely have to complete a QFD chart for each component of the plane with a long list of requirements. The chart is also commonly known as the house of quality because of the shape. If you want to learn more about QFD check out a good quality management book like this one by S. Thomas Foster or this article by Kenneth Crow. If you want to try building your own house of quality, I’ve attached a template you can download.

Duluth Trading Ad Duluth Trading Ad Trying to differentiate yourself in an over saturated apparel market is difficult. If you want to stand apart by price you need to beat H&M, Primark, and Uniqlo. If you want to win for trend and lead time to market you need to beat Zara. Those are tall orders. There are several US retailers still producing quality apparel and winning market share through messages of quality and value. The target markets vary and many offer style with quality. Focusing on comfortable, durable, versatile garments can be a winning formula. Despite what fast fashion would have us believe, not everyone buys a new wardrobe every season. Many people are looking for garments that last. Articles regarding minimalism and living with less are popping up everywhere from Refinery 29 to The Washington Post. Although in some cases, minimalism is being marketed as a look, more than a lifestyle. Even those who follow the latest trends still buy basics to wear along with trendier items. Designed for End Use Quality guru, Joseph Juran, defined quality as fitness for use. Does the product work for the end use the consumer intends? This is the primary focus of all imagery and messaging from Wisconsin based Duluth Trading. The focus makes sense for a work-wear brand. Customers want to know that clothing won’t interfere with movement while working. Not too many other companies focus on telling customers about shirts that stay tucked in or flexible work pants. Duluth Trading continues to expand stores and sales were up for the third quarter.  Stock Manufacturing Co - Interior Pant Image Stock Manufacturing Co - Interior Pant Image Durability A prime example of messaging quality and durability is Colombia Sportwear Company’s tested tough commercials. The commercials show the company’s founders wear testing garments in extreme, but amusing situations. Customers want to know that outerwear garments will stand up to the elements. Other outerwear companies outfit explorers and athletes to create a similar message of reliability under extreme conditions. Record third quarter sales for Colombia Sportswear prove the company has created a message that resonates with their target market. Chicago based Stock Manufacturing Co markets quality garment features using interior garment photos for many items. This allows the customer to see the actual components and sewing. The other advantage is the customer sees the care that went into selecting trim materials. If the customer perceives the manufacturer put thought into engineering the garment, they will perceive greater value.  Everlane Cost Breakdown Everlane Cost Breakdown Value Is it possible to capture younger consumers by focusing on quality? Everlane has created a brand image based on supply chain and cost transparency. They focus on offering stylish basics made of beautiful fabrics. While they advertise primarily through social media, they supply enough information for bloggers and others to keep their message consistent. Explaining the cost structure allows consumers to feel they are getting a value and that the retailer is not receiving an unfair portion of the retail price. The margins are usually calculate to 60% to 65%. All indications are that the Everlane is continuing to rapidly grow. While the garments are stylish, they are still versatile, core pieces to a wardrobe. You won’t find anything that will only be worn for one season. Even an upscale brand can tell a value story. By explaining design decisions and where products are made, consumers can be made to feel like they are investing in clothing. Todd Snyder uses videos and copy to explain why certain design details are put into garments and why he chooses to collaborate with particular manufacturers and brands. The use of video allows the details of the product to be shown. This video also showcases the manufacturing facility, letting the customer feel connected to the whole production process. The brand was recently acquired by American Eagle to take advantage of the success of the more casual Tailgate Clothing brand. The tailored portion of the designer’s business continues to grow both in the US and Japan, as told in this NY Times article. None, of these companies were overnight superstars or achieved growth because they suddenly started marketing the quality of their products. They built in the quality as part of the brand from the beginning and slowly built a consistent message with products that supported the message. Perceived quality is important to marketing, but the customer cannot be dissapointed when the product is received. Next week I’ll focus on designing quality into the product from the beginning of development. |

|||||||