|

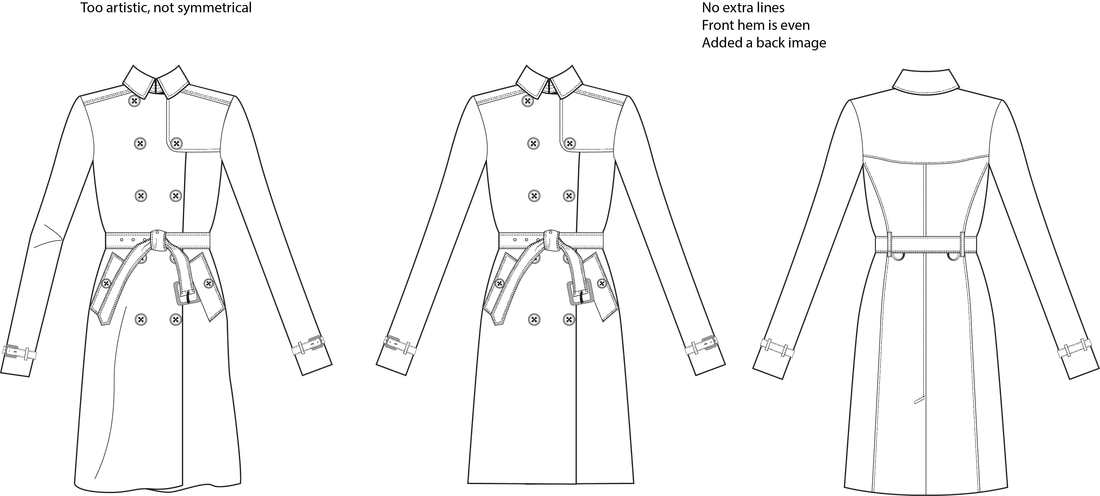

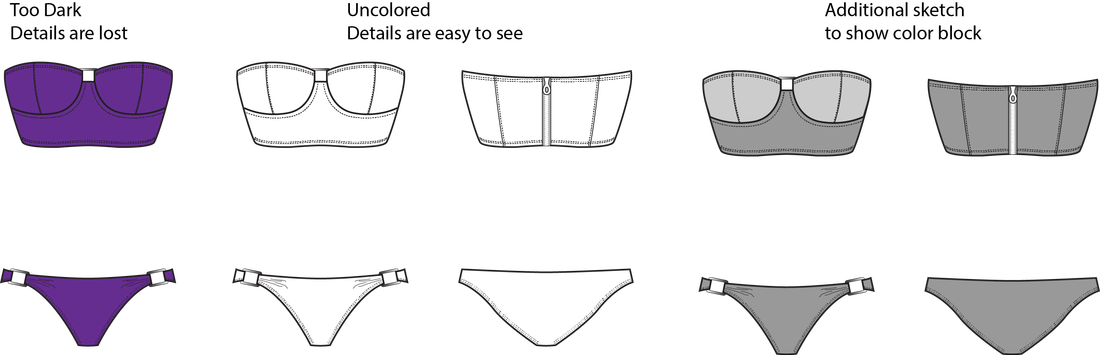

The designers I work with think I sit at home with kids' activity books where you identify what is different about one image from the other. In my case, it is one sleeve has a cuff and the other doesn't or only one side of the collar has top stitching. Fashion illustration is a wonderful art form and can convey the vision for a clothing line or style. However, the flat sketches used to communicate with a manufacturer need to be free of artistic embellishment. Countless times I've received sample garments from a manufacturer with an issue only to look at the sketch and find the factory followed the sketch exactly. Some basic tips for flat sketches:

There are various opinions on whether to include the inside of the back collar / interior of the garment on a front sketch. I believe as long as the image is clear either way is acceptable.

**If you aren't well versed in stitch types American and Efird has a great resource on their website that shows common stitch types. Feel free to comment with additional suggestions or resources!

0 Comments

Change is difficult. Asking designers, technical designers, product developers, suppliers, merchandisers, buyers and others to accept the use of virtual samples is a BIG CHANGE!

I have created some steps that may help as you add 3D virtual samples to your product development cycle. These recommendations are based on the 2010 book Switch: How to Change Things When Change is Hard by Chip Heath and Dan Heath. I highly recommend the techniques in this book for approaching any type of change. Motivate the Rational Side Focus on the bright spots What other process improvements have already succeeded in reducing your product development lead times? Analyze why these worked. Highlight the success. Give specific changes Break down the steps for each function. What specific steps will technical design do? What specific involvement will design have in reviewing the virtual samples? How much time will be involved? Make the process more tangible and specific. Point to the Destination Develop a specific goal. Preferably a giant, audacious goal that can be achieved! Reduce the number of samples per season by 300! Take a month out of your product development lead time! Feed the tip jar. If you have already made progress toward the goal, announce it. We are going to reduce samples by 300 per season and we already reduced by 60 samples last season through other process improvements! Motivate the Emotional Side Is your team already tired, over-worked, and think that asking them to do something differently is going to add work? You are going to need to motivate them emotionally. Find the Feeling What would happen if you put all the samples you dropped during the development cycle last season in one room? That is a powerful visual. Remind them what previous process changes or technology integration felt like in the beginning. Drawing on a computer versus hand sketching took more time initially. Using a PDM or PLM system to create specifications was scary at first. Would you turn back now, NO! Shrink the Change Try the new process for a season and then evaluate. Try the process for only one product category. Grow Your People Cultivate an identity of technically savvy, industry leaders. Don’t take away the artistry, but enhance the process. Shape the Path Tweak the environment Make the process easy. Use easy to complete forms to request initial samples. Create a central location for all related documents. Nominate one person to handle all questions. Build Habits Create checklists or better yet, use your product lifecycle management system. Ugh you say! These can be helpful in making sure you didn’t forget anything. What does the screen print on the front of that T-shirt look like in all the sizes? Do we need to review each size? Create lists for which styles should be reviewed in 3D and record if they were. Rally the Herd Let the behavior spread. Provide a way for all involved to give feedback and be involved in adjusting the process as needed. Have a plan to quickly scale-up the use of 3D virtual samples as excitement grows. Lacey Bell |