|

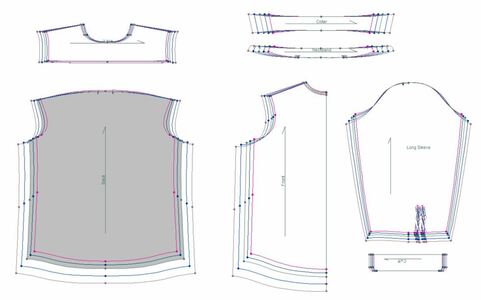

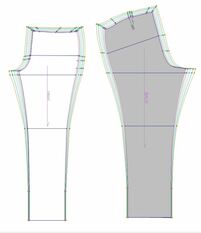

Clients are sometimes puzzled why an apparel pattern-maker or pattern grader asks so many questions. As a pattern grader I want to be sure your designs fit your customers. Your customers should be able to buy the same size each time they make a purchase. The work I do must be both accurate and consistent. The grade should be consistent between the styles I work on and the styles anyone else has graded for you. You might think there are hard and fast rules to grading garments. There are not. Asking questions demonstrates your grader knows what they are doing. No one is questioning the skills of a pattern grader you have used previously. We want to help you create a consistent fit. When should you worry? When your pattern grader doesn’t ask questions. If you tell them you want to run the style in women’s sizes 2-16 and the grader doesn’t ask anything before grading, that is a problem! There is no industry standard for how much each size should grade. You put in a lot of work to get to this point. You have created a garment that fits great in one size. A well graded pattern maintains the integrity of this work across all sizes. A poorly graded pattern jeopardizes all your hard work to date. Questions Your Pattern Grader will ask? What’s your base size? This is the original size the pattern was created to fit. Who is your target customer? Age? Fitness level? Ethnicity? Will the style be alpha or numeric? Alpha sizes are combined sizes, like a women’s Medium (8-10). If alpha which sizes are combined? Equivalent sizes are pretty consistent in the industry for men but alpha size equivalents for women change between brands. A women’s size Medium might be 6-8, 8-10 or 10-12. Size Charts A basic size chart like you use on your website to help your customers find the right size, tells us your basic body width grade. Unfortunately, the size chart usually only gives us basic width measurements such as chest, waist, and hip. The size chart doesn't tell me your customers are mountain climbers in which case I will grade the shoulder width differently than for a brand marketed to seventy-year-old bird watching enthusiasts. Below is a picture of a graded shirt. Each dot is a grade point. You can see the chest, waist, and sweep are only a few of the points graded.  Measurement Charts from Previous Styles If you have been developing apparel for multiple seasons, you may already have a graded measurement chart for the new style you want graded. Your pattern grader should follow that chart. If not, the grader may ask to see charts from previous styles. Measurement charts are usually included in technical packages/specifications. If one person created all previous measurement charts for your brand, they should follow a consistent system. All neck widths should grade the same. All body lengths for knit tops should grade the same. All long sleeves should grade the same. More points are included than the size chart. Previous Graded Patterns The holy grail! Previously graded patterns tell us the grade points on the measurement chart but additional things like the grade distribution and additional grade points that may not be on the measurement chart. Measurements like armhole depth are not frequently included on a garment measurement chart; but help your grader more than the final armhole circumference. Reviewing the grade distribution on pants is especially important. Many people in the industry have different opinions on how much of the grade to place at the rises versus the side seams. I can achieve the same measurements as someone else but the distribution might be different. Usually the goal is to keep every size shaped the same. Occasionally we will break that rule. As an example, we may allow the front rise angle to shift if you think your customers over a certain size have a more pronounced belly. If we ask to see a previous pant you have run; we are only asking to confirm the grading “philosophy” that has been used on your styles in the past. Will we blindly copy your previous patterns? No. If we find something unusual, we will ask you about the issue. There may be a valid reason the pattern is graded that way. But we won’t perpetuate an error. Don’t Worry If You Don’t Have Answers If you don’t have the information requested by the pattern grader, don’t worry. I will gladly help my clients determine the right grading for their target market. I do charge a consulting fee for this work. I do not make the same recommendation to every client. We discuss who your competitors are and the demographics of your target market. I’ll review your competitors’ grades and size charts. I’ll review available anthropometric data for your target market. I’ll grade the type of styles you intend to create before finalizing the grade. Then I’ll create a template that all your measurement charts can be started from to maintain consistency. Sometimes we meet well established brands that have several different factories making products and they have relied on the factory for pattern-making and grading. Unfortunately, I can almost guarantee inconsistencies. Pattern-makers and graders do great work, but every grader and pattern-maker has their own methods. If you are in this situation, you need to create consistent measurement grade rules and graded block patterns. Block patterns are appreciated by graders. They can import a digital block pattern and copy the grade rules directly to the new style. Using graded blocks guarantees consistency in grading. This way you can work directly with the best factory for the product type without worries about consistency. For more information on grading visit our previous post on Reviewing Nested Graded Patterns. For more information on what a block pattern is, we recommend What is a Block from Fashion-Incubator. Copyright 2019 Fireflyline LLC

0 Comments

Leave a Reply. |